SKU: SKU:SMOT-AZULA-1HEXP

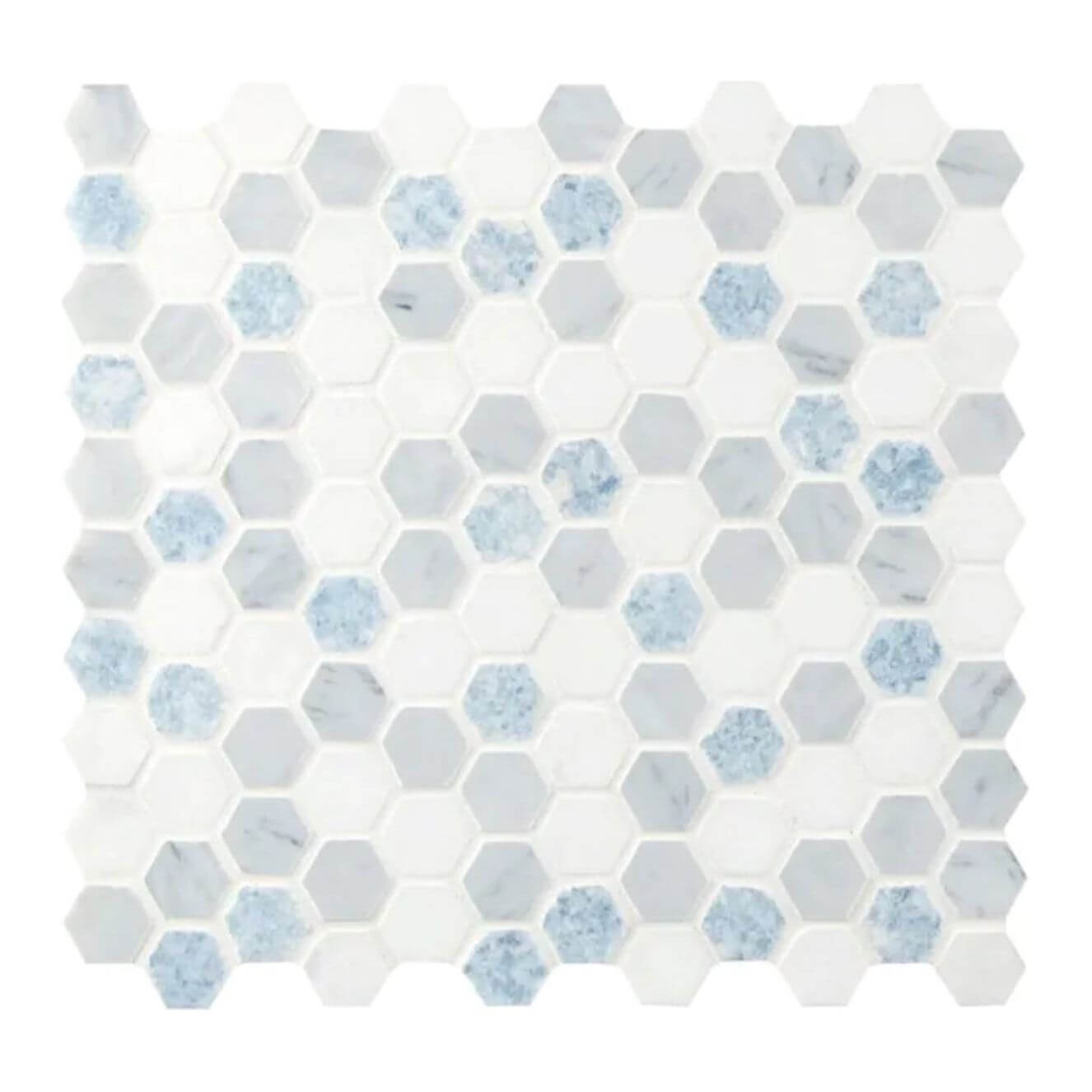

MSI Azula Hexagon 11.81x11.61 x10 mm Polished Marble Mosaic Tile

MSI Azula Hexagon 11.81x11.61 x10 mm Polished Marble Mosaic Tile

(0.96 sq.ft.)

How many tiles do i need?

*We recommend adding an additional 15% to your overall square footage calculations to ensure you have enough coverage for waste and reserve during the installation process.

You need

0 Sheet & 0 SQ.FT.

Total price: $16.45

Couldn't load pickup availability

MSI Azula Hexagon Polished Marble Mosaic Tile

Color and Finish:

- Primary Colors: Creamy whites, grays, and blues

- Finish: Polished

Dimensions:

- Sheet Size: 11.81 inches x 11.61 inches

- Tile Thickness: 10 mm

- Individual Tile Size: 1-inch hexagons

Applications:

- Indoor: Ideal for backsplashes, countertops, and bathroom walls

- Outdoor: Suitable for exterior applications due to frost resistance

Features:

- Design: Iconic hexagon shape with a playful, updated pattern

- Installation: Mounted on mesh-backed sheets for easy installation

- Certifications: Greenguard Indoor Air Quality Certified®

Durability:

- Resistance: Semi-vitreous and frost-resistant, making it suitable for various environments

- Maintenance: Requires sealing with a penetrating sealer to maintain its appearance and durability

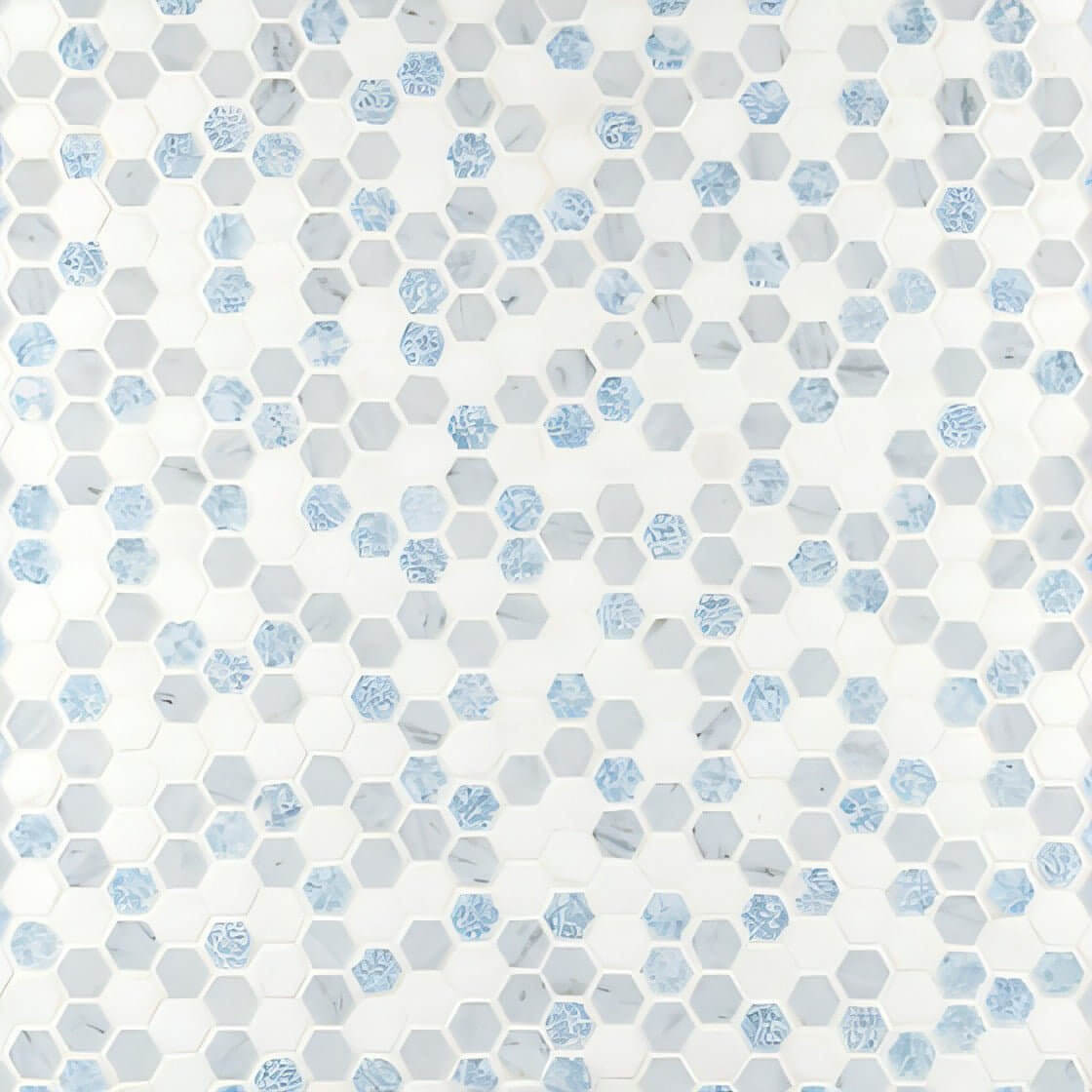

Shade Variation

Shade Variation

Colors and textures may vary slightly between tile batches due to natural manufacturing variations. For a clear representation, we recommend ordering a sample. Learn more.

-

Customer Servive

Smooth start-to-installation journey, focused on customer excellence.

-

Free Shipping on Samples

Test it out, risk-free. Free shipping on sample orders.

Shop Now -

Guaranteed Safe Checkout

Protected by advanced encryption. Your information is safe with us.

-

Fast and Insured Shipping

Speedy delivery with guaranteed protection for your peace of mind.

Processing & Shipping

- Orders take 48 hours to process and about a week to be delivered depending on your location.

- Orders may come in multiple packages and may be delivered separately.

- All freight orders require a signature at time of delivery.

- All freight orders are delivered curbside.